Giant 3D printers could soon be far more accessible. Northwestern University scientists have developed a new 3D printer using a technology called HARP (high-area rapid printing). With a HARP printer, the scientists can print an object the size of a human adult within a few hours.

Northwestern's HARP is 13 feet tall with a 2.5 square-foot print bed. It can print about half a yard in an hour, which the university says in a press statement is "a record throughput for the 3D printing field," and a wide variety of large and small objects at the same time.

"3D printing is conceptually powerful but has been limited practically," says Northwestern's Chad A. Mirkin, who led the product's development, in the statement. "If we could print fast without limitations on materials and size, we could revolutionize manufacturing. HARP is poised to do that."

While HARP is still just being used internally, Mirkin says it will be available for sale commercially within 18 months.

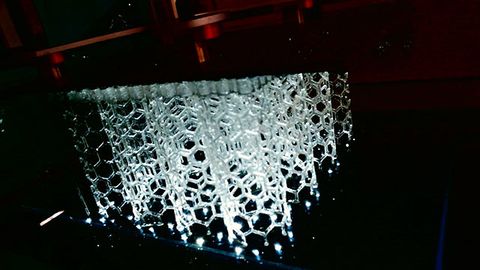

HARP uses a new version of stereolithography (SLA), a type of 3D printing that converts liquid plastic into solid objects. Using an ultraviolet laser pointed at a surface of a liquid thermoset resin, SLA 3D printing first draws an object's support structures, and then the object. Breaking the object into layers, 3D printing company Protolabs says SLA printing has "high accuracy" for details "as small as 0.002 inches."

3D printers generally stay small because the technology can generate a tremendous amount of heat, especially at high speeds. "When these printers run at high speeds, a great deal of heat is generated from the polymerization of the resin," says David Walker, a researcher in Mirkin's lab. "They have no way to dissipate it."

Until now. Using a nonstick liquid that Northwestern says "behaves like liquid Teflon" that flows through the window built into HARP, heat is removed and circulated through a cooling unit.

"Our technology generates heat just like the others," Mirkin says. "But we have an interface that removes the heat."

"The interface is also nonstick, which keeps the resin from adhering to the printer itself," James Hedrick, another researcher in the lab, says in the statement. "This increases the printer's speed by a hundredfold because the parts do not have to be repeatedly cleaved from the bottom of the print-vat."

There are currently ways to 3D print large objects, of course. In 2016, the Guinness Book of World Records awarded the U.S. Department of Energy (DoE) a certification for the largest 3D printed object ever printed, an SUV-sized tool used to make airplane wings. That process took 30 hours, and the DoE described the printer as a "giant" that needed to be stored in a warehouse.